SUPPLYING CHEMICAL PRODUCTION TECHNOLOGIES WORLDWIDE

EXCELLENCE IN ENGINEERING, FABRICATION & TECHNICAL SERVICES

-

VESSELS & EQUIPMENT

LEARN MORE -

INSPECTION

LEARN MORE -

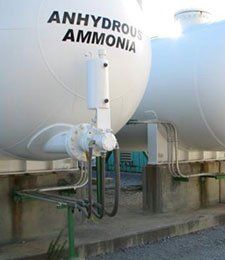

AMMONIA SERVICES

LEARN MORE -

MACHINE SHOP

LEARN MORE

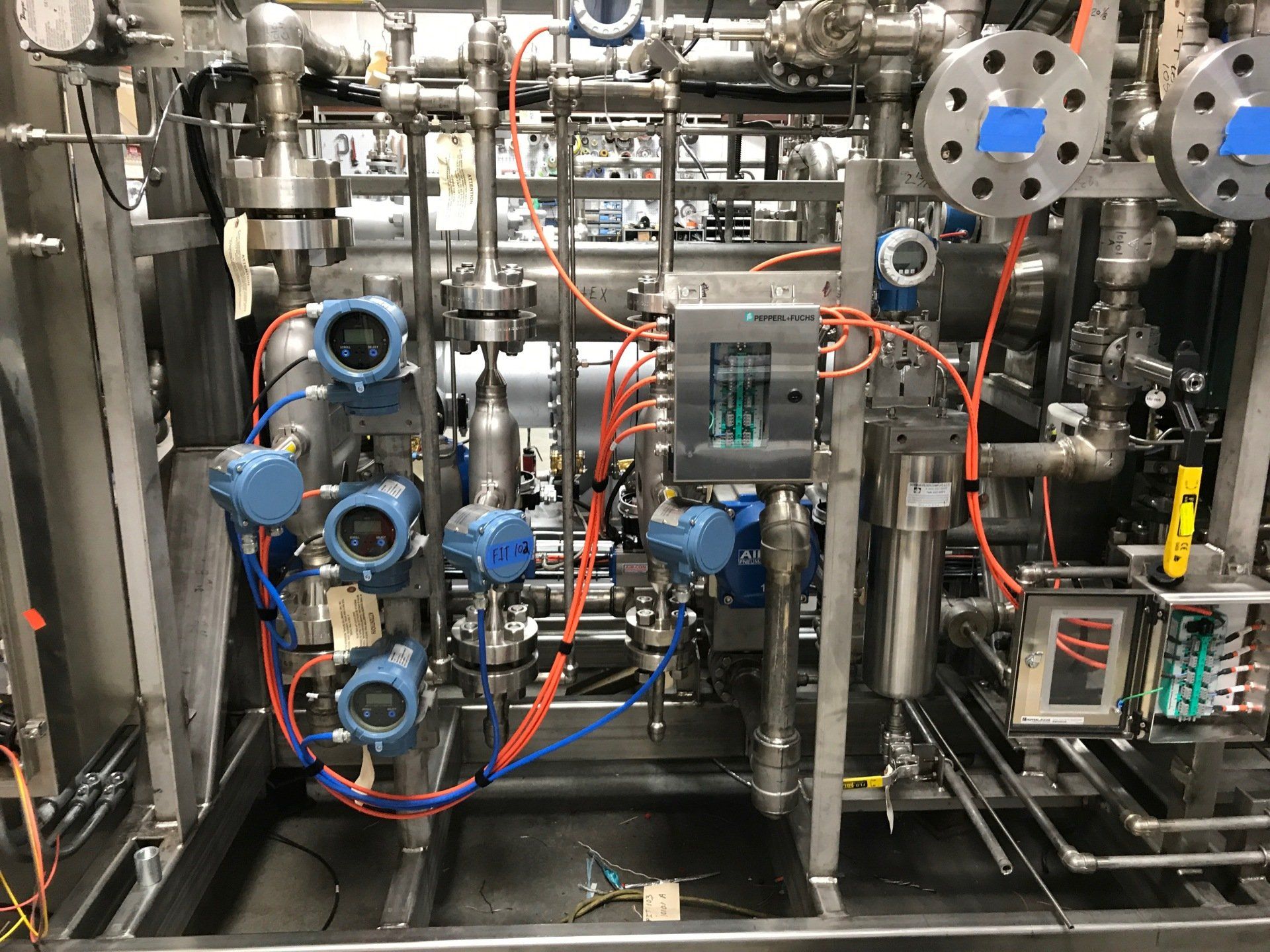

ASME VIII/ANSI CHEMICAL PROCESS EQUIPMENT MANUFACTURER

PRODUCTS & SERVICES

Certified Welding of most alloys Large and small jobs

Fabrication of Tubesheets, Inconel, Specialty Flanges, Hastelloy

OUR NATION WIDE FIELD SERVICE DEPARTMENT

ABOUT ENVIRONMENTAL EQUIPMENT SERVICES

EEServ has been serving the energy and chemical industries providing ASME pressure Vessels, Heat Exchangers, Flanges and chemical engineering services since 2006. The managers of the company are hands on fabricators, field service technicians, engineers and project managers, so they have an excellent working knowledge of the industry.

Our goal is to make the entire design and fabrication process seamless and fluid. With the addition of the machine shop to our facility, we can achieve even tighter control of the process from start to finish.

Our customers are a diverse group, ranging from LNG suppliers to algae processing companies to the United States Department of Justice. They are located as far away as South Africa, Morocco, and India and as close as Arizona! Our ability to work across a wide variety of industries and locations demonstrates a broad knowledge base and shows the trust our customers place in us.

If you have a complex chemical process that requires the very best in process equipment engineering,

design, fabrication and operational testing, we can provide that for you.

We help get your process equipment to where it needs to be.

CONTACT US WITH YOUR PROJECTS

Hours Of Operation

Monday - Friday: 7:00 a.m. - 4:00 p.m. MST24/7 Emergency Service Available

Call Us

(865) 789-3176

Service Area

Worldwide

Email

Office@eeserv.com

All Rights Reserved | Environmental Equipment Services