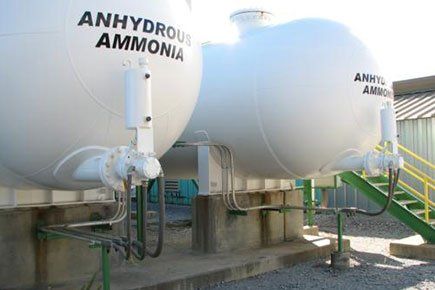

AMMONIA SERVICES

AMMONIA PUMP OUT SERVICES FOR TANKS AND AMMONIA REFRIGERATION SYSTEMS, PSM COMPLIANCE AUDITS, HAZOP EVALUATIONS AND PROCESS REVIEWS

EEServ's field service representatives can be on site for new commissioning of ammonia systems to PSM, HAZOP review to complete P&ID safety and compliance review. With our equipment, we can oversee everything from oxygen removal prior to the first fill of ammonia, to full commissioning of your systems up to sending ammonia to the AIG. For ongoing systems we offer full ammonia pump out and reclamation of ammonia with no environmental waste. These include ammonia refrigeration systems.

Our team has designed, built, and installed ammonia systems for utility companies in the United States and India. Our experience allows us a expert understanding of Ammonia services and the processes of storing, vaporizing and delivering ammonia very well.

COMPLETE SUPPORT

CONTACT US TO TALK ABOUT OUR AMMONIA SERVICES.

AMMONIA & CHEMICAL SYSTEM INSPECTIONS

AMMONIA LEAKS/PIPING AND TANKS EVACUATIONS

AMMONIA TANK PUMP OUT SERVICES

- EEServ has the equipment to safely transfer liquid, drain liquid and vacuum remaining vapors from ammonia tanks of all sizes to assure safe entry and inspection.

- We can safely reclaim all of your ammonia from piping and storage tanks during inspections.

- This task requires the right experience, the right tools and the right personnel to assure the project is done safely