LARGE PART CNC VERTICAL TURNING LATHE CUSTOM ANSI FLANGES, TUBESHEET, RINGS AND DEEP DRILLING SHOP

VERTICAL TURNING LATHE EXOTIC ALLOY LARGE FLANGES AND TUBESHEET DRILLING CENTER SERVICING PHOENIX, TUCSON, LOS ANGELES AND SAN DIEGO

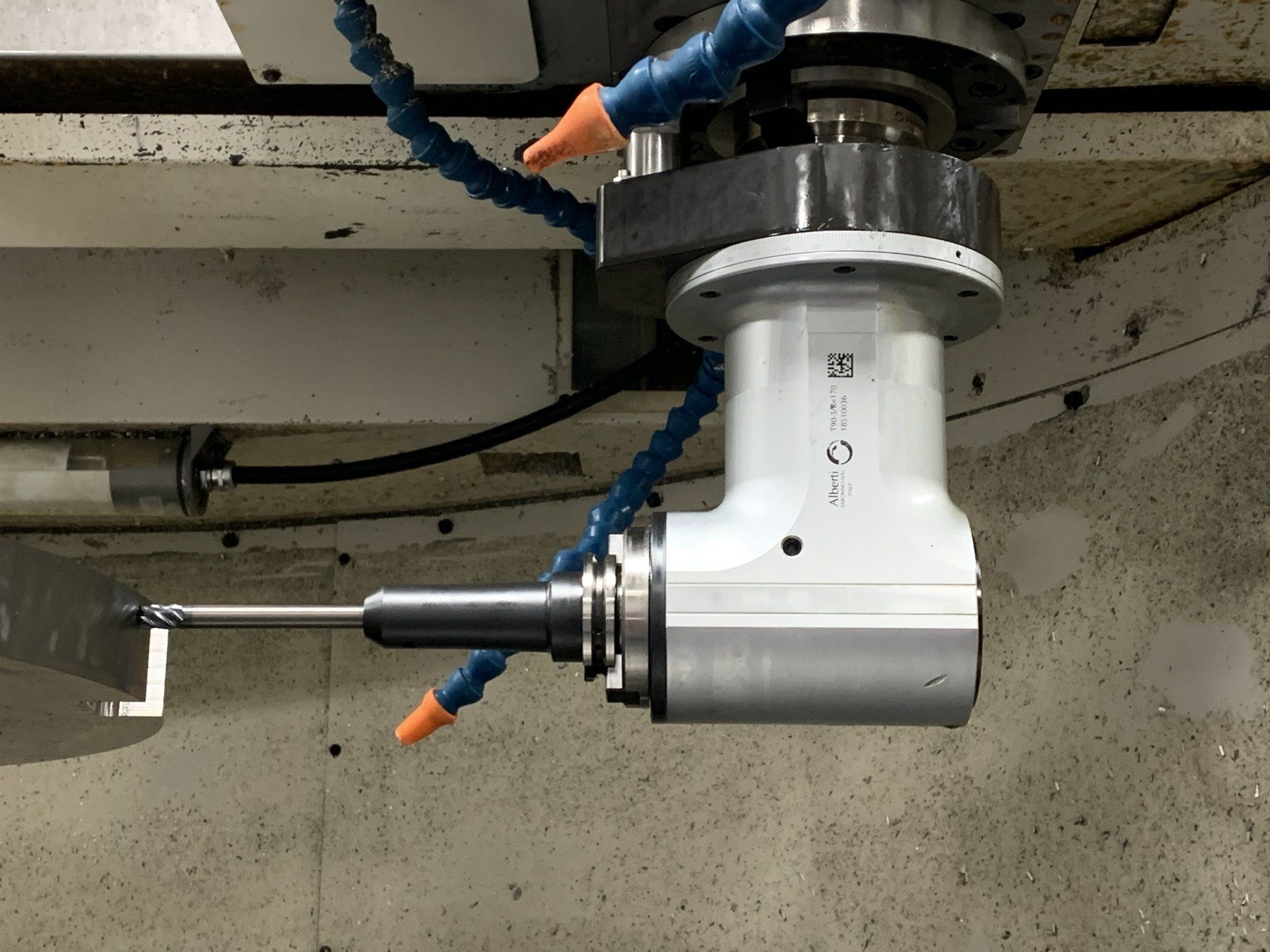

Large part CNC Vertical Turning Lathe Mighty Viper VTL-20-25 with 20 HP live tooling. This machine is capable of angle milling and turning on one machine without moving part to another machine. We are capable of weldments using ASME Code certified procedures for complete fabrication needs including partial data reports for pressure vessel fabrication. Inconel and Hastelloy are our specialties for fabrication and machining. We can supply fast machining of large ANSI spec flanges out of rolled and welded rings, plate or forgings

Vertical and horizontal milling and grinding

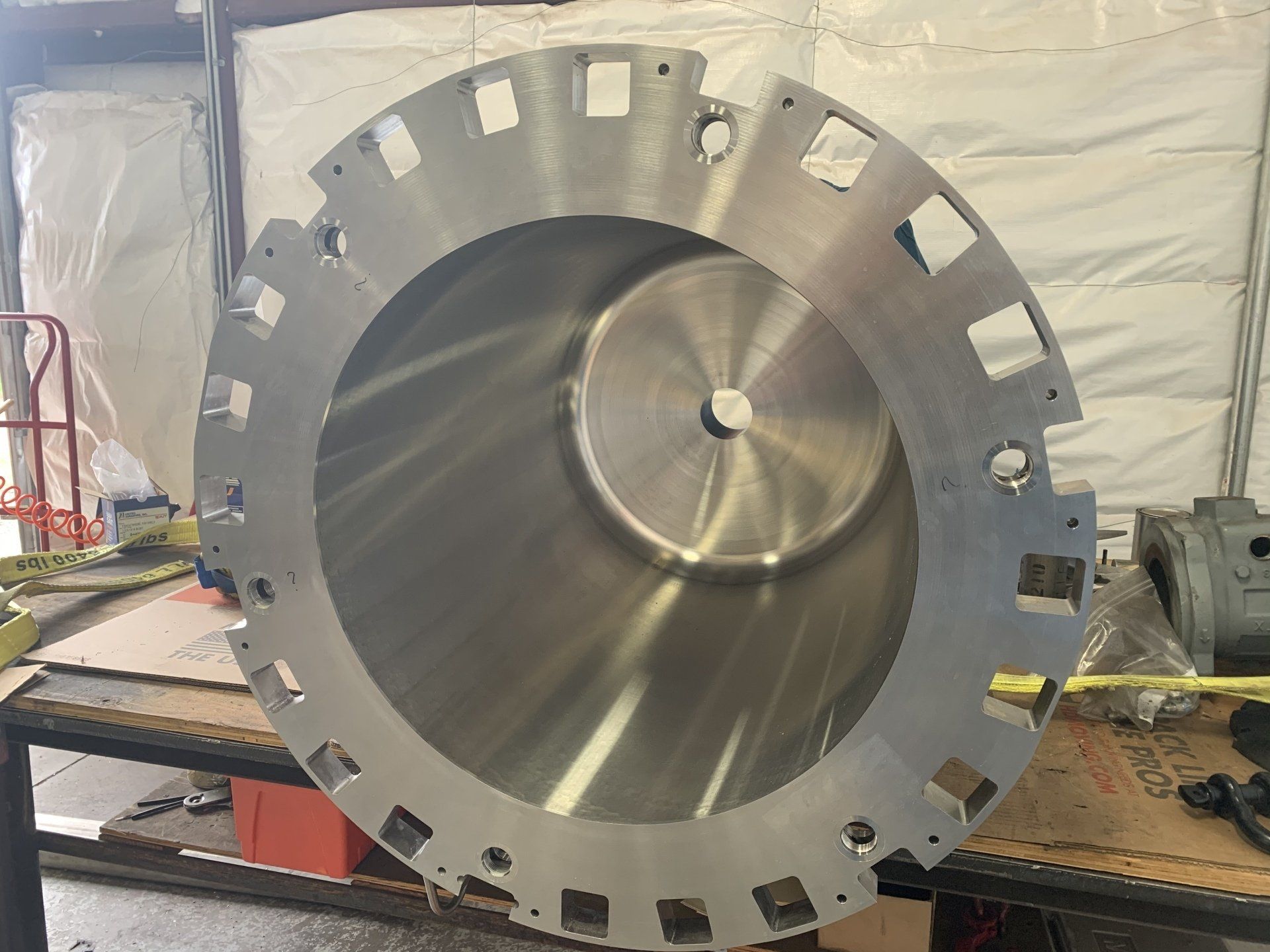

Expedited Large Body and Piping Flanges Custom Made up to 85" in outside diameter.

Four axis turning boring and drilling

CAPACITIES

Max turning diameter 85”

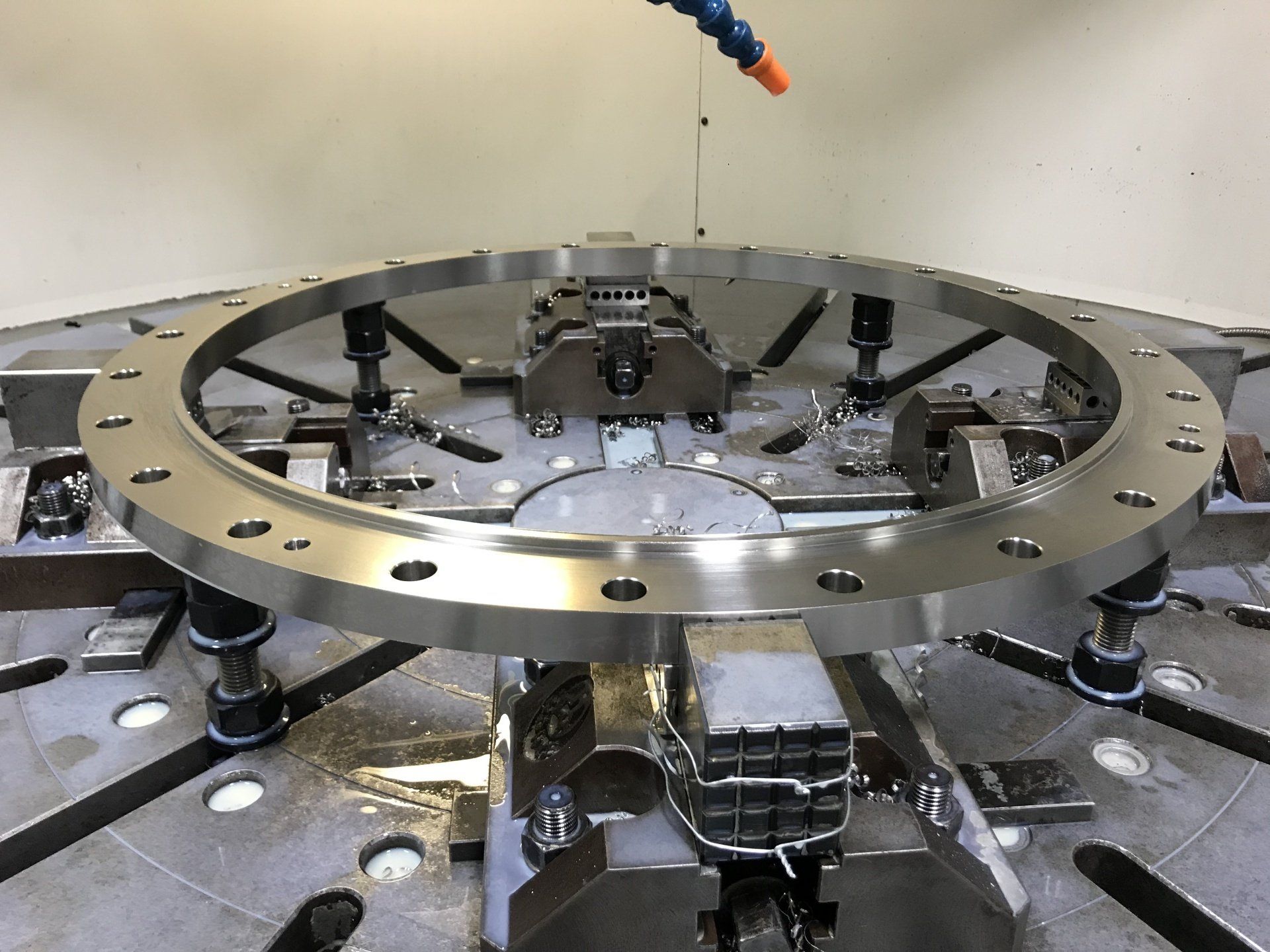

Machine Shop Large Part CNC VTL 3 Axis Mill-Turn Vertical Turning Lathe VTL

IN-HOUSE MACHINING

EEServ's Vertical Turning Lathe taking the first cuts on 5,800 pound 316L forging. This is a little over 10% of what the Viper can handle. With that power, it allows for rapid removal of stock and then finish cuts to 0.0005" - amazing for such a huge machine!!

Allow us to look at your large machining requirements as well as close tolerance, intricate and multi-process works and let's see if we can accommodate your requirements.

EEServ's Vertical Turning Lathe makes a complex process simple as the part remains in the machine through each step thus incredible tolerances can be held during each step of the process.

Because we are able to integrate all of the steps - including, but not limited to, process engineering, design, machining, fabrication, pilot operations to initial plant operations - we can take a project that appears complex initially and bring it in under one roof assuring complete singular responsibility throughout your project.

Changes are far easier to deal with in a vertically integrated shop from drawings changes, code calculations all the way down to main BOM changes are done with one intervention. Process required changes from engineering down to skid or vessel fabrication can be made by our customers far easier when its all under our supervision.

Because of our knowledge of exotic alloys in welding and machining as well as having a history of usage experience with them exposed to extreme acids, bases, erosive environments and extreme temperatures we can guide you in this selection to assure your process equipment survives your process requirements.

If you're looking for that one of shop that you can take you from concept to production, fill in a slot with a specific process train, a single skid or vessel anywhere along the line, let us look at your requirements.

EEServ has a can do attitude to all the projects brought to us for consideration. If we have the ability to do the task we will find it and move forward.

From high Nickle alloys such as Inconel 825, to 2# foam EEServ has a solution to your large machining issues.

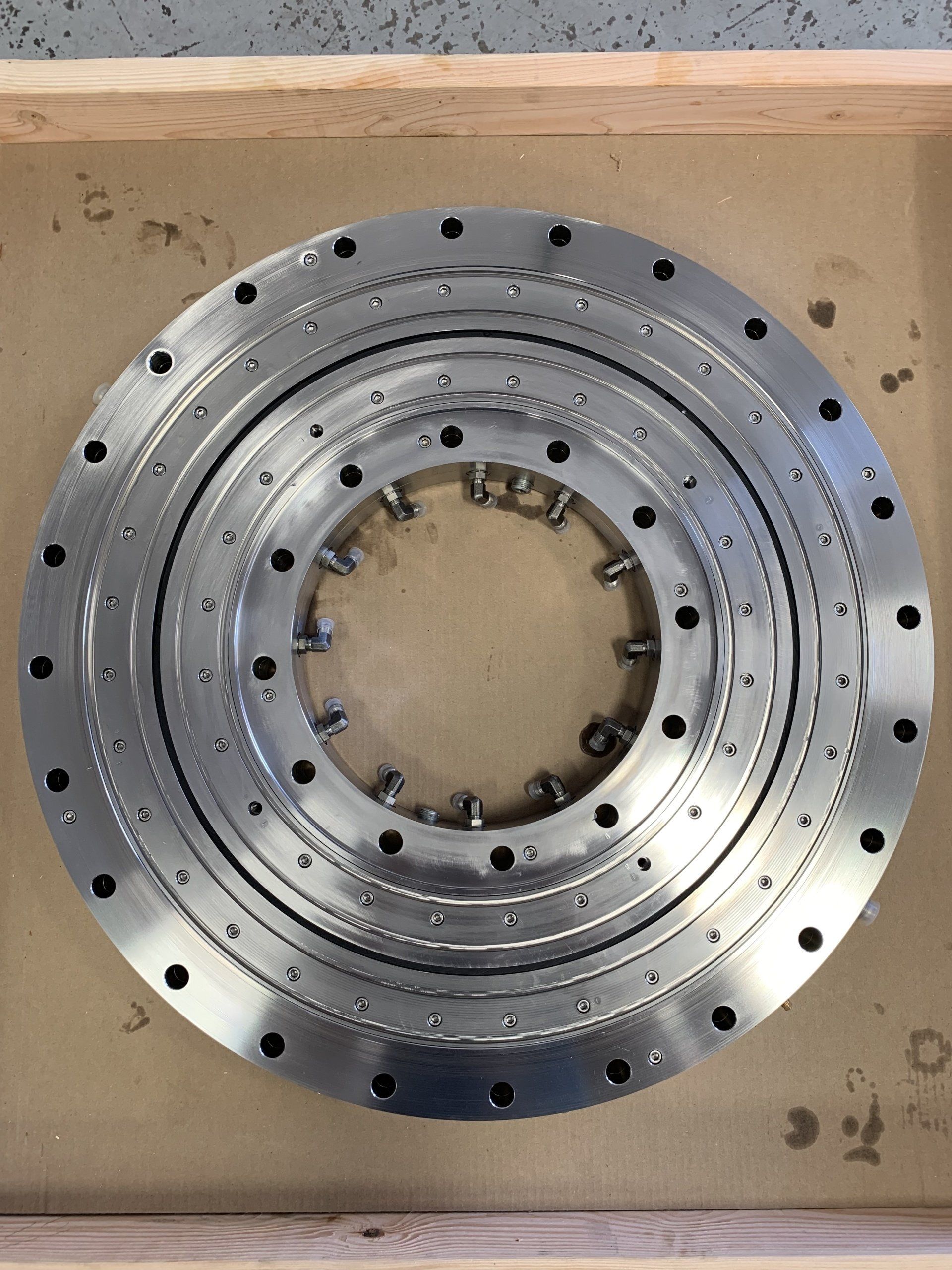

DEEP DRILLING

EEServ has the equipment to tackle deep hole drilling in thick flanges and tube sheets. Within tool cooling and lubrication EEServ can drill deep holes in all complex materials and thicknesses quickly and a greatly reduced cost. Depths beyond 13 x drill diameters depending on materials and sizes.